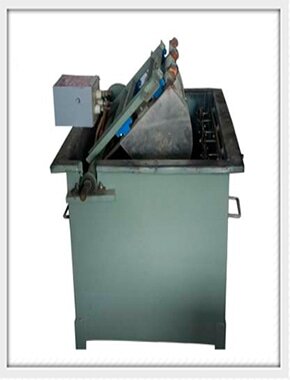

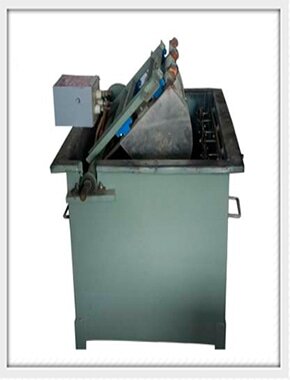

Water starter is a resistor which has a liquid resistance element. It is also called Liquid Resistance Starter (LRS). It is used to supply power to the driving motor while varying resistance. These starters range upto 2500 H.P. of slipring induction motor. We manufacture our starters with stainless steel blade contacts as it does not corrode in salty water thus lives much longer than M.S. blades which is one of the reasons why we are called best water starter manufacturers in India.

We use DMC insulators which have a high capacity to withstand heat. We are one of the best water starter manufacturers in India because our main focus has always been quality instead of quantity. We have skilled manufacturers in our team and the products confirm all the standards and safety measures set by the government. The LRS also contains heavy copper contacts and are installed in such a way that it prevents sparking. Also, the tanks are manufactured using heavy gauge M.S Sheet and coated with rubber coating and rubberised paint with PVC lining to prevent rusting. All the connections are based on studs which are given in a separate box which provides better connection and wiring facilities to reduce breakdown of machinery and increase efficiency.

We have supplied this starter to a wide range of applications in mines, cement plants,steel industries and water treatment associated industries. The aim to design this starter is to provide smooth acceleration to full load speed and increase torque control.

Some of the advantages of the water starters are shared below: (Give <H3> Tag in above heading)

Appropriate for a wide range of standards and specific applications

The electrodes are manually controlled.

It needs comparatively less maintenance

For the last three decades, we are Water Starter Manufacturers In India and have now set an example on the standards of quality and excellence. We have installed all stainless steel and brass bolts which remain dipped into the tank for most of the time. Also, we use premium quality copper wire bars for all the moving and stationary contacts.